Paperwork

I've really shied away from creating any sort of timeline pressure on this build. I've always wanted to be able to work on the project, or if I felt like it, not touch it for weeks at a time. However that is now over as I've submitting my initial paperwork to the FAA and the clock is ticking!

I dug out the 'Step-by-Step Certification Guide' that had been sitting in my office for the last 3 years and gave it a look through. Not sure if EAA still offers these, but for the $12 or so it cost it's well worth it. You can find similar information out just searching but the guide shows you examples and literally is a checklist for the process. In short here is what I sent off the to FAA:

- AC Form 8050-1 Aircraft Registration Application: This came with the above mentioned EAA guide, however you can also go to your local FSDO and pick one up. If you've ever bought or sold an airplane it will look familiar. Whatever information you put on this will need to match your airplane info; builder, serial, model. For me I kept it pretty basic (Last Name, First Name, Builder Number, RV-10)

- FAA Form 8050-2 Aircraft Bill of Sale: You request this through Vans ensuring you give them the same information you're using on the 8050. It all has to match.

- FAA Form 8050-88 Affidavit of Ownership for Amateur Built Aircraft: I downloaded and filled out this form. It has to be notarized as well.

- $5 Check

Make copies of the above and mail to the FAA PO Box on the forms. Being local I took it to the actual post office where the PO Box is. I still had to pay for shipping but I assume it made it to the box safe and sound. It's suggested you give them around 90 days to process this through. I'm aiming for a March/April first flight so my plan is to submit the next batch of paperwork (Special Airworthiness Certificate) in about a month.

Progress

With the weather getting near or below freezing I've not been going to the hangar on a daily basis as I did the first week. That hasn't slowed me down because on top of doing paperwork, planning and ordering odds and ins I've been doing my 'Homework'. In fact one of my homework items was to finish up lights for the wing tips and clean up the empennage fairing.

This, as with most fiberglass was a fairly tedious cycle of sanding, filling, sanding, ect. Particular to the wing tip lights there was a lot of sanding to get the cutout hole the exact size without having it too large. This is done with 150 grit or so slide between the light and the side and just worked around until you have the spacing you want. Because of the temps I had to move the project out of the garage and into the kitchen so everything cures correctly.

My only complaint is the CS pull rivets were not long enough to capture the inside mount. This was mainly due to me building up the inside of the tips for strength. So it's not as smooth as I would like, however once painted I doubt it will bother me at all. Will be taking these back to the hangar now for future wiring.

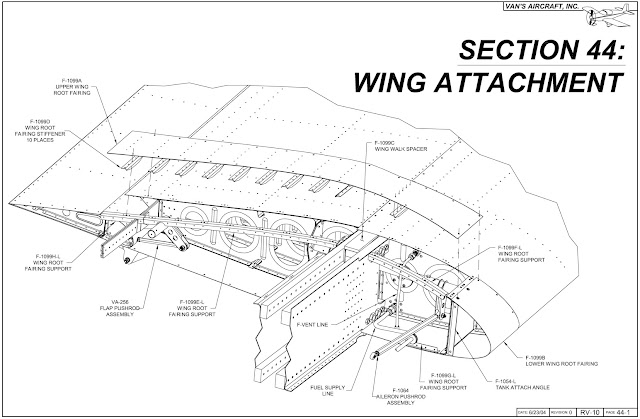

Onto hangar activity, I was able to take advantage of a few warm days to work on wing attachment items as well as final fitting the empennage fairing. I am just about done with all wing attachment steps but will make a separate post with pictures once I'm complete. I will however show my variation from the plans with a really good looking aftermarket vent from

JD Air.

The problem I was trying to solve was around fuel vent freezing. If the vent freezes it stops the air into the gas tank which restricts the tanks ability to feed fuel to your engine. That's bad! I was talking to Tom with

TSFlightlines about this issue and was thinking of using a check valve or something. He directed me over to JD Air who makes a vent that helps mitigates this problem by having two openings. Not to mention it looks really slick.

Installation was extremely easy, you just install it to your wing root bottom piece and then bend some 1/4 tubing to connect it all. I had tried to avoid ever making lines but Tom suggested instead of spending $45 on braided lines to connect this that a rigid line was best. Having excluded this material from my kits I went to Ace Hardware and picked up two 12" sections of aluminium tubing for $1.80 a piece. I then swung by Harbor Freight and picked up a $10 bending tool. That along with my 30+ year old flare tool I was able to make some solid first time vent lines which fit perfectly.

Another item I've spent some time on is the empennage fairing. I've become a bit obsessive compulsive on fiberglass work. From the factory I was happy with the fitting of the fairing and there was a good 1/4 gap between the front of the horizontal stabilizer and the fairing piece. I was able to essentially force it into place but it then required me to rebuild a few of the edges a bit. I also deviated from the plans in terms of attachments. For example I tapped all the holes on the bottom for #6 screws which include the ones that tie into the vertical stabilizer. I also didn't dimple or countersink any portion that was under the fiberglass. For whatever reason there are several holes that the plans ask you to countersink but are covered with fiberglass, which is counters sinked so the piece behind it can be flat. The picture on the above right shows the gap fairing which turned out well.

I am 31 nut plate installations away from completion of the empennage section. I need to work on some rigging items, connecting the rudders and such but rigging I consider it's own little thing. Here's a good picture of where it sits now.